Effect of Curing Time on the Physicochemical and Sensory Properties of Beef Jerky Replaced Salt with Soy Sauce, Red Pepper Paste and Soybean Paste

Article information

Abstract

This study was done to investigate the quality properties of beef jerky with soy sauce, red pepper paste, and soybean paste replacing salt. Sliced beef samples were cured in salt (control), soy sauce, red pepper paste, and soybean paste for 24 or 48 h and then dried at 70°C for 8 h. Treatments showed higher final moisture content and lower Na+ concentration than the control after drying for 8 h. The lightness and shear force values were lower in all treatment samples than in the control during 48 h of curing time. In particular, lower lipid oxidation was found in the jerky cured with red pepper paste than in the control. Sensory evaluation showed that color, flavor, and tenderness of jerky samples were improved by replacing salt with soy sauce, red pepper paste and soybean paste, and higher likeability scores of the beef jerky were obtained among those treatments after 48 h of curing time.

INTRODUCTION

Jerky is one of the oldest meat products that is preserved by salting and drying. It is relatively simple to process, has a typical flavor, and needs no refrigeration during commercial distribution due to its low water activity (aw) (Yang et al., 2009a). To achieve stability, jerky is dried to aw 0.70 to 0.85 (Quintion et al., 1997). Hurdles to microbial survival and growth include drying temperature, low aw, and preservatives such as salt and organic acids depending on the composition of the marinate mixture (Gailani et al., 1986; Quintion et al., 1997).

Salt is the most commonly used functional ingredient in processed meat product, and is used primarily for flavor but also has secondary functions including inhibiting microbial growth, extending shelf-life and increasing protein hydration (Han et al., 2011). It increases protein hydration by increasing the ionic strength in meat products, and increased protein hydration leads to increased water binding in intact muscle pieces and increased soluble protein concentrations in meat products (Chinachoti and Schmidt 1991).

However, the meat industry has explored various options to lower sodium in processed meats (Lim et al., 2013). In recent years, an increased effort has been made to reduce the amount of salt in foodstuffs (Costa-Corredor et al., 2009). There is a trend to reduce the salt content in foods because excessive sodium intake contributes to high blood pressure in salt susceptible consumers (Hee and Mac Gregor, 2010). There is considerable evidence that food consumption is strongly related to health, and that high levels of sodium intake may be crucial for the development of hypertension and the age related rise of blood pressure typically observed in modern society (McCarty, 2004).

To improve the sensory qualities of jerky, we introduced the East Asia, including Korea, traditional sauce such as soy sauce, red pepper paste, and soybean paste as the marinade. The East Asia traditional sauces are produced from soybean with 5% to 20% of salt for several months at the ambient temperature. Soybean and soy foods have been used as beneficial dietary and nutritive materials in several Asian countries due to their high quality proteins (~40%) and many other functional substances like phenolic acids and isoflavones (Zhang et al., 2003). Also, soybean or soy foods may be effective in reducing the risk of heart diseases and various cancers. Furthermore, an intake of soy proteins or soy isoflavones decreased to the diastolic blood pressure, serum total cholesterol, or low density lipoprotein (LDL)-cholesterol in the subject groups with high or normal cholesterol level (Anderson et al., 1995).

One of the most important attributes of jerky is the curing time that can be measured as quality properties. It has been demonstrated that processing time affects aroma and flavor traits (Flores et al., 1997). The curing time is also correlated to lipolysis (Andres et al., 2005), which is one of the main degradation mechanisms affecting lipids during meat processing (Larrea et al., 2007).

Therefore, the objective of this study is to investigate the effect of different curing time on the physicochemical and sensory properties of beef jerky with salt replaced by soy sauce, red pepper paste and soybean paste, and to determine if curing agents can be effectively utilized for beef jerky processing.

MATERIALS AND METHODS

Preparation of beef jerky samples

A total of five cattle (Hanwoo, Korean native cattle, market weight 425 to 455 kg) were randomly selected at a slaughter plant. The muscle of beef semimembranosus (BS) was dissected from each carcass 48 h postmortem. All subcutaneous and intermuscular fat and visible connective tissue were removed from the fresh muscles. The sample was sliced to 0.5 cm thick pieces with a meat slicer (HFS 350G, Hankook Fujee Industries Co. Ltd, Hwaseong, Korea) and cut into cubes of 15.0×4.0×0.5 cm. Sliced BS muscles were cut parallel in the same direction as muscle fibers. Commercial salt, soy sauce, red pepper paste and soybean paste were purchased from a local food additives plant. Salt, soy sauce, red pepper paste and soybean paste solution were diluted with water to the same salinity (15%) content. The salt-water was prepared by dissolving sodium chloride in distilled water and its salinity adjusted to 15% salt as the same salinity of soy sauce, red pepper paste and soybean paste. The red pepper paste and soybean paste solutions were homogenized with a Polytron homogenizer (T25-B, IKA Sdn. Bhd., Rawang, Malaysia) at 8,000 rpm for 30 s. The slurry was filtered through two layers of cheese cloth to remove the particles. The sliced samples were then cured for 24 h or 48 h, in a cure solution containing 10% water, 2% salt solution (soy sauce, red pepper paste, and soybean paste), 6% sugar, 0.2% pepper, and 0.028% sodium nitrate (based on raw meat weight; v/w).

After curing, all samples were dried using a dryer (DS80-1, Dasol Scientific Co. Ltd, Hwaseong, Korea) at a temperature of 70°C. There was adequate air distribution between samples receiving the same drying treatment. Water activity measurements (AQS-2, Nagy mess system, Gäufelden, Germany) were then taken, to the target aw<0.80. Jerky samples were recorded at 1 h intervals throughout drying. The ultimate aw of control and treatments samples after 8 h of drying was 0.75 to 0.77. Dried products, in general, have been considered as one of the safest food groups for humans since they involve hurdles to microbial survival and growth. After drying and cooling to ambient (25°C) temperature the jerky samples were loosely packed, without vacuum, plastic bags (single package). The moisture content, pH, lightness, shear force, salinity, Na+ concentration, thiobarbituric acid reactive substance (TBARS) and sensory evaluation were measured at 24 and 48 h of curing time. A flow diagram depicting beef jerky preparation is shown in Figure 1.

Moisture content

Moisture content was determined according to AOAC (2000). The strips were dried in an air oven at 102°C for 24 h and the total moisture content of individual beef strips was determined from their pre-dry and dry weights expressed as the percentage of pre-dry weight and gram water per gram of dry weight.

pH

The pH was measured in triplicate using a digital pH meter (MP230, Mettler-Toledo, Greifensee, Switzerland). Approximately 3 g of the jerky sample was cut into small pieces and 27 mL of distilled water was added. Slurry was then made using a homogenizer (T25basic, IKA, Rawang, Malaysia) and pH was recorded. The pH meter was calibrated daily with standard buffers of pH 4.0 and 7.0 at 25°C.

Instrument color

The surface lightness color value of the jerky samples were measured by the Commission internationale de I’éclairage (CIE) L* system using a Minolta Chroma meter CR-200 (Minolta Camera Co., Osaka, Japan), whereby measurements are standardized with respect to a white calibration plate (Y = 93.5, x = 0.3132, y = 0.3198).

Shear force

Shear force (N/cm2) was measured using the Instron Universal Testing Machine (Model 3343, Instron, Norwood, MA, USA) with a V-shaped shear blade. From six samples, 0.5×4.0 cm cross sections (across to the fibers) were cut for cutting force measurements. The beef jerky samples were placed at right angles to the blade. The crosshead speed was 100 mm/min and the full scale load was 49 N.

Salinity

The salinity was measured a digital salinity meter (Takemura, TM-30D, Tokyo, Japan). Approximately 3 g of the jerky sample was cut into small pieces and 27 mL of distilled water was added. Slurry was then made using a homogenizer (T25basic, IKA, Malaysia) and salinity was recorded.

Na+ concentration

About 1.0 g dried beef jerky was put into burning cup and added pure 20 mL HNO3. The sample was incinerated in microwave oven at 200°C temperature. Before each element read in equipment, standards at different concentrations for each element were read in inductively coupled plasma atomic emission spectrometer (ICP-AES). Then, quantitative concentrations were determined with an ICP-AES.

2-Thiobarbituric acid reactive substance (TBARS)

The 2-TBARS content of beef jerky samples from each treatment was determined using the thiobarbituric acid (TBA) distillation procedure by Yang et al. (2009a) as modified from a procedure by Sinnhuber and Yu (1977). A 0.4 g sample of beef jerky was weighed into a 30 mL screw capped pyrex tube (PYREX, Tewksbury, MA, USA). Two to 3 drops of antioxidant solution (A: 0.3 g butylated hydroxyl anisole+5.4 g propylene glycol, B: 0.3 g butylated hydroxyl toluene+4.0 g tween 20), 3 mL TBA solution, and 17 mL TCA-HCl solution (trichloroacetic acid+0.6 N HCl) were added. The mixture was vortexed and then incubated in a 100°C boiling water bath for 30 min to develop color. The sample was cooled in cold water for 10 min. A 5 mL supernatant solution was transferred to the 10 mL glass tube, 2 mL of chloroform was added and centrifuged for 15 min at 2,000×g. The absorbance of the resulting supernatant solution was determined at 532 nm against a blank sample containing all the reagents minus the sample.

Sensory evaluation

Beef jerky samples from each treatment were evaluated by an 8-member trained expert descriptive attribute sensory panel in the Gyeongsang National University. The panelist were selected and trained according to the procedures of Meilgaard et al. (1999). Panelists were given samples representing anchor points for each attribute, and training sessions using dried beef with/without soy sauce, red pepper paste, and soybean paste in the meat lab. The panelists were trained using a 9-point scale (“9 extremely intense” and “1 slightly intense”) for color, dried beef flavor, soy sauce/red pepper paste/soybean paste flavor and texture attributes. Final anchor point ratings were decided upon by training panel after initial evaluation and discussion.

For the samples, panelists evaluated the samples for appearance, color, off-flavor, juiciness, tenderness, and overall acceptability using a 9-point hedonic scale as described by Meilgaard et al. (1999), where 1 meant “extremely dislike” and 9 meant “extremely like”.

Statistical analysis

Data from three replications were analyzed by analysis of variance (ANOVA) using statistical analysis systems (SAS, 2000). The ANOVA was adopted for designing the mathematical model using SAS 9.2 (SAS Institute, Inc., USA). Duncan’s multiple range tests were used to determine the statistical significance among the means at a significance level of 95%.

RESULTS AND DISCUSSION

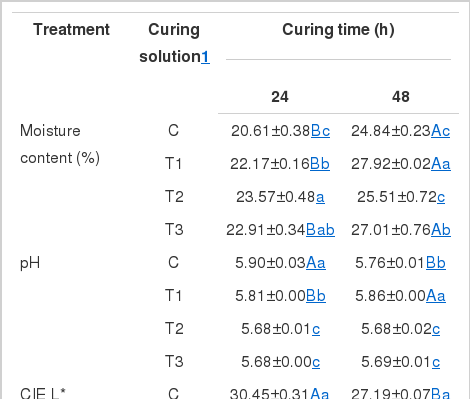

Moisture content, pH, lightness and shear force

The results of moisture content, pH, lightness and shear force are presented in Table 1. In this study, the moisture content of beef jerky samples ranged from 27.92% to 20.61%. The final moisture content of beef jerky increased with increasing curing time (p<0.05). The final moisture content was higher in all treatments than in the control sample at 24 h of curing time. At 48 h of curing time, soy sauce (T1) and soybean paste (T3) had higher moisture content than the control. Moisture content has a decisive effect on the stability of intermediate-moisture (IM) foods (Labuza et al., 1970). In general, commercial IM foods have moisture contents of 20% to 40% (Jose et al., 1994). When manufacturing IM food, it is important to control the water content because aw is closely related to aw (Leistner, 1987). This relationship between moisture content and aw may be very effective for controlling the quality and sensory properties of the jerky. This is one of the benefits of controlling the textural properties of beef jerky. Specific changes in flavor, texture, and stability of processed meat products have been associated with relatively narrow aw ranges (Chang et al., 1991).

The pH values varied from 5.90 to 5.68. The pH value of all treatments was significantly lower than that of the control sample at 24 h of curing time (p<0.05). Particularly, T2 and T3 had lower pH vales than those of other jerky samples until 48 h of curing time (p<0.05). Joes et al., (1994) reported that the average pH for IM meat products was in the broad range of 4.72 to 6.73. Leistner (1987) reported that low pH can inhibit or delay the spoilage of various dried meat products by mold and microorganism growth. Also, the pH values of soy sauce, red pepper paste and soybean paste solutions were 6.72±0.02, 5.03±0.01, and 5.24±0.01 (not presented). Therefore, this shows that the pH value of beef jerky can be affected by curing ingredient.

The lightness value increased during curing 48 h in the T2 sample. However, the lightness values of control, T1 and T3 jerky samples decreased with increasing curing time (p<0.05). In comparison to the control, the lightness value was significantly lower in all treatments than the control sample during 48 h of curing time (p<0.05). Color is a major factor in consumer purchase decisions because it is presumed to be indicator of meat quality (Brewer et al., 2002). The surface color values of beef jerky can change according to the marinade ingredients at the same temperature, and the CIE L-value decreases with soy sauce, red pepper paste, and soybean paste solutions (Lim et al., 2013). Consequently, in the present experiment the replacement of salt with soy sauce, red pepper paste, and soybean paste solutions changed the color attributes of the beef jerky by decreasing lightness.

Texture is also an important factor in the preparation of meat products and in consumer preference (Guerrero et al., 1999). One of the most important attributes of jerky is also the hardness, which can be measured as shear force. The shear force values can be used to characterize the IM products, and is defined as the maximum force attained as a blade shears through beef jerky samples. The shear force values of the samples varied from 92.02 to 72.62 (N/cm2). In comparison to the control, the shear force value was significantly lower in all treatments than in the control sample until 48 h of curing time (p<0.05). The low shear force levels in soy sauce, red pepper paste, and soybean paste replacement cured samples seem to be due to high moisture content. These results agree with a previous report on the shear force or hardness being affected by moisture content (Yang et al., 2009b).

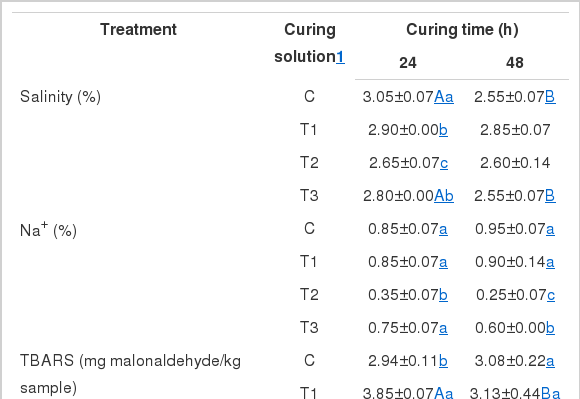

Salinity and Na+ concentration

The results of salinity and Na+ concentration are presented in Table 2. Salt is a commonly used functional ingredient in processed meat products, but the meat industry has explored various options to lower sodium in processed meats (Lim et al., 2013). Salinity values of all beef jerky samples showed a decreasing trend with increased curing time. Particularly, the salinity value of the control and T3 beef jerky samples decreased with increasing curing time (p<0.05). The salinity of all treatments was significantly lower than that of the control at 24 h of curing time (p<0.05).

The Na+ concentration of beef jerky samples varied from 0.95 to 0.25 with curing time, and all beef jerky samples did not show significant changes in Na+ concentration during 48 h of curing time. The T2 jerky sample showed lower Na+ concentration than those of other samples at 24 h of curing time, and the T2 and T3 jerky samples showed lower Na+ concentrations than those of other jerky samples at 48 h of curing time. Therefore, it is suggested that replacing salt with red pepper paste and soybean paste could be used to reduce the Na+ concentration of the meat products, providing consumers with healthy food.

2-Thiobarbituric acid reactive substance (TBARS)

The TBARS value is the most common indicator used to measure the degree of lipid oxidation in meat products (Obanu, 1988). Lipid oxidation is a major cause of deterioration in the flavor, odor, taste, color, texture, and appearance of meat and meat products (Aalhus and Dugan, 2004). The results of TBARS value are presented in Table 2. In this study, the T2 and T3 jerky samples showed lower TBARS values than the control sample for 24 h of curing time (p<0.05). The TBARS value of beef jerky containing red pepper paste was significantly lower than those for the other treatments for 48 h of curing time (p<0.05). Also, the TBARS value of the T2 and T3 beef jerky samples increased with increasing curing time (p<0.05). It is normally accepted that the TBARS value increases in meat with increasing storage time. Particularly, TBARS values became higher as drying time increased (Chen et al., 2002) and were dependent on the salt concentration (Sárraga and Garćia-Regueiro, 1998). We found that there was a significant effect of the Na+ concentration on lipid oxidation. It seems that the different curing ingredients may help to form malonaldehyde throughout the curing. Also, soy sauce contains several antioxidants such as melanoidins (formed during fermentation), phenolic compounds and free amino acids. Gochujang (Korean red pepper paste) possesses various biological activities, including anti-obesity (Ahn et al., 2006), anti-mutagenic (Choo, 2000), and anti-cancer effects (Kim et al., 2005). Soybean paste contains large amounts of isoflavone aglucons and phenolic acids (Chung et al., 2011).

Sensory evaluation

Sensory panels were convened to assess the effects on the color, flavor, off-flavor, juiciness, tenderness and overall acceptability of beef jerky samples (Table 3). The most important sensory attributes of jerky (and other snack foods) are texture, color and flavor, which are determined by the raw material and numerous technological factors (Albright et al., 2000). All sensory attributes were significant (p<0.05) in regard to the salt and replacement of the soy sauce, red pepper paste, and soybean paste. The color scores of the beef jerky after replacing salt with soy sauce, red pepper paste and soybean paste were higher than those of the control sample (p<0.05). Further, the color scores of all jerky samples increased at 48 h of curing time. The flavor scores were significantly higher in all treatments jerky samples than in the control (p<0.05). The juiciness and tenderness scores were significantly higher in all treatments jerky samples than in the control during 48 h of curing time (p<0.05). The overall acceptability scores were improved by replacing salt with soy sauce, red pepper paste, and soybean sauce at 48 h of curing time (p<0.05). Also, the overall acceptability scores ranged from 6.22 to 4.60, with higher acceptability obtained from the beef jerky, in which salt was replaced with soy sauce, red pepper paste, and soybean paste at 48 h of curing time (p<0.05).

The soybean is an important food for the supply of essential amino acids, unsaturated fatty acids, isoflavones, phytic acid, saponin, trypsin inhibitors, thchpherol, and oligosaccharides in traditional Korean dietary food (Chung et al., 2011). These substances are the origins of the unique flavors and aromas of the soy beans. Among the various amino acids, it is known that arginine is a good contributor to the salty taste (Breslin and Beauchamp, 1997). The texture of jerky-type snack foods is one of the most important sensory attributes (Lee and Kang, 2003). The jerky’s texture can be altered by the moisture content, as is done for other IM meats (Farouk and Swan, 1999). Therefore, it is suggested that replacing salt with soy sauce, red pepper paste, and soybean paste in beef jerky could be used to increase flavor, texture and the overall acceptability of meat products, and provide the consumer with a new food containing these ingredients.

CONCLUSION

This study has demonstrated that replacing salt with East Asia traditional sauces such as soy sauce, red pepper paste and soybean paste can decrease Na+ concentration, lightness and shear force, and enhance the final moisture content and sensory acceptance (color, flavor, tenderness, and overall acceptability) of beef jerky. In particular, the sensory evaluation of beef jerky was enhanced with increasing curing time. Also, replacing salt with red pepper paste and soybean paste resulted in lower lipid oxidation values. The replacement of salt with soy sauce, red pepper paste and soybean paste had a positive effect on quality properties and on reducing the Na+ concentration of beef jerky. Therefore, in conclusion the addition of Korean traditional sauces can contribute to the development of reduced-salt meat products with desirable quality characteristics.

ACKNOWLEDGMENTS

This research was supported by Rural Development Administration (Project No. PJ009848).

The authors thank the Ministry of Education and Human Resources Development for the financial support of the BK21 plus program in Korea. Hyun-Jung Lim and Eun-Young Jung were supported by a scholarship from the BK21 plus.